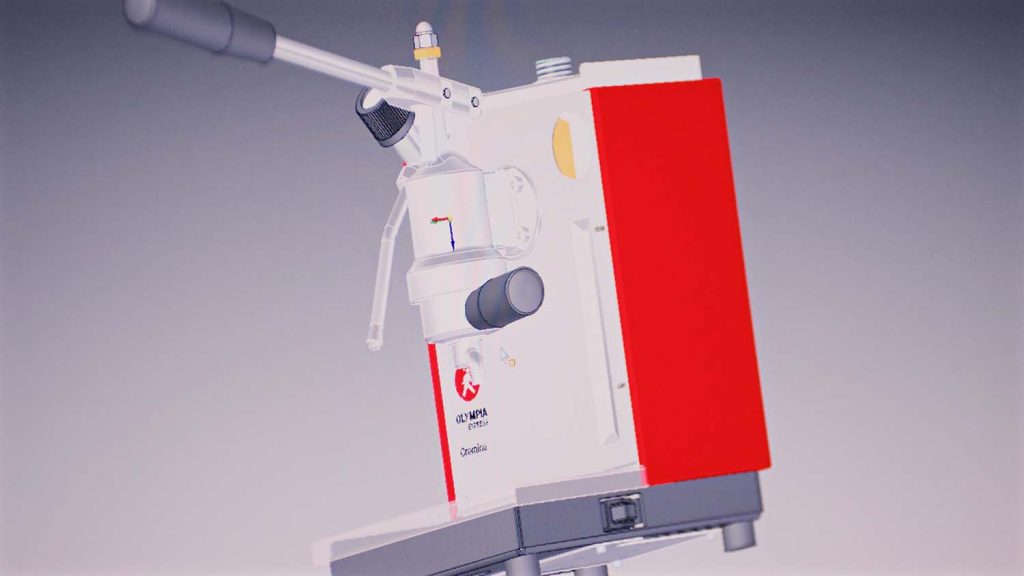

Makers of the finest Swiss-made Espresso makers, Olympia Express has a heritage of building precise machinery for home baristas. With the introduction of Siemens Digital Industries software, opportunities not previously possible have been brewing, learns Emilie Eisenberg

Prized by coffee experts, for over 95 years Olympia Express’ espresso machines have built a cult following in its home of Switzerland and around the world.

Selling for over £3,000, the handbuilt machines are built with a reliability that boasts longevity and prestige.

“Our products make coffee to the quality of an Italian coffee bar with a machine that is just a fraction of the size and cost of a professional machine,” says Olympia Express CEO Thomas Schätti. The key, he says, is that they are built like a professional machine, with the same care, quality materials and careful design.

“We build our machines for a small eternity – they are designed and built to last multiple lifetimes and their use should be a celebration of making an outstanding coffee!”

Since Schätti AG acquired Olympia Express in 2011, the manufacturing of its products has taken place in Glarus, Switzerland, with the help of Siemens Solid Edge software.

“When we took over the company, the previous owners had designed in 2D. Solid Edge allows us to create highly accurate 3D models which streamline our production process from design to manufacturing,”

“We remodelled all the parts of the machine in Solid Edge and made new models as well as spare parts. And since then, we have made various design iterations and improvements to the machines.”

Solid Edge has sped-up the design process and reduced the number of physical prototypes needing to be built, saving important time and money, he explains.

Now, Olympia Express also uses Siemens Teamcenter software for product lifecycle management, and NX CAM software during the manufacturing process for secure control of data and efficient design reviews.

Its design team reports that it has reduced prototyping efforts by 50 per cent and has seen a 30 per cent increase in productivity since their integration.

“We rely on Teamcenter to manage our product data and enhance collaboration across our teams, keeping all design data in one place,” says Schätti.

The design team continues to develop new designs with the help of Solid Edge, announcing in June 2024 the release of Mina, a lightweight, portable espresso machine.

They were able to reuse 3D data from previous projects on Solid Edge to create the design without having to start completely from scratch. The visualization capabilities within Solid Edge are used for internal communications and to help service machines.

Alongside new projects, digital transformation has allowed the company to assist with the service and maintenance of existing machines, some of which are over 50 years old. Creating spare parts is quicker and easier than before, with the engineering team using an exploded view of the Solid Edge CAD model to see which parts of an older machine are needed and how best to replace them.

Olympia Express has plans to fully utilise the Siemens Xcelerator platform – giving the team further access to more Siemens software tools – to create truly sustainable products that also build on the company’s heritage of exceptional quality and perfect coffee.