For the designers at Goodwin Hartshorn, it’s solving the most technical challenges that often leads to the most beautiful results. Stephen Holmes speaks to the studio’s co-founders about their hands-on work crafting the latest luxury earbuds for Bowers & Wilkins

Everyone’s ears are different. In fact, your own right ear and left ear may well be quite different from each other. That makes it extremely challenging to design a universally comfortable earbud. Since 2003, design studio Goodwin Hartshorn has been developing products for luxury British audio brand Bowers & Wilkins, from loudspeakers to wearables.

A recent focus has been the development of two new pairs of earbuds, the Pi6 and Pi8 models. These mark a change in direction for Bowers & Wilkins from from its previous Pi5 and Pi7 models, which were developed by another design house. While the earlier models have been a commercial success for the company, the fit they offered was not perfect for every customer. This was an aspect of the product the company was keen to improve.

“I would say a large proportion of our process is about the surfaces, the design for manufacture, the aesthetics and so on,” says Goodwin Hartshorn co-founder Richard Hartshorn. “And it’s often critical that we solve some technical problems to almost release the industrial design, to allow the industrial design to progress.”

The Pi6/Pi8 project began with a deep dive into the ergonomics of earbuds, he explains. The agile nature of the studio’s design process, meanwhile, meant that a great deal of focus was also dedicated to understanding variances in ear shapes and sizes. The race was on to make wearables that would truly outshine the competition, not just in performance but also in comfortable fit.

This meant studying the shapes and dimensions of human ears, and in particular, the cavum concha (the section of an ear where the earbud nestles), as well as the ear canal and its angle relative to the cavum concha.

The design studio consulted a broad variety of data gathered around the world, including 3D scans of many ears, all of which helped them to identify ‘critical users’.

As Hartshorn points out: “There isn’t much point in doing a load of testing for people in the middle of the spectrum. You might as well concentrate on the people with the smallest ears and the largest ears, because they’re your critical users.”

Give these critical users a comfortable fit, he reasons, and you can be pretty sure you’re providing a comfortable fit for every other customer.

Studying the human ear led to a set of constraints from which initial CAD models were created in Solidworks. “We wanted to use Solidworks because it’s parametric. We knew there was going to be a process of refinement. Doing it parametrically would make those refinements more easy,” says co-founder Edward Goodwin.

Process of elimination

The goal in this project was to iterate on various design ideas within the specified constraints as quickly as possible, printing new forms of the earbuds every day using a Formlabs Form 2 3D printer.

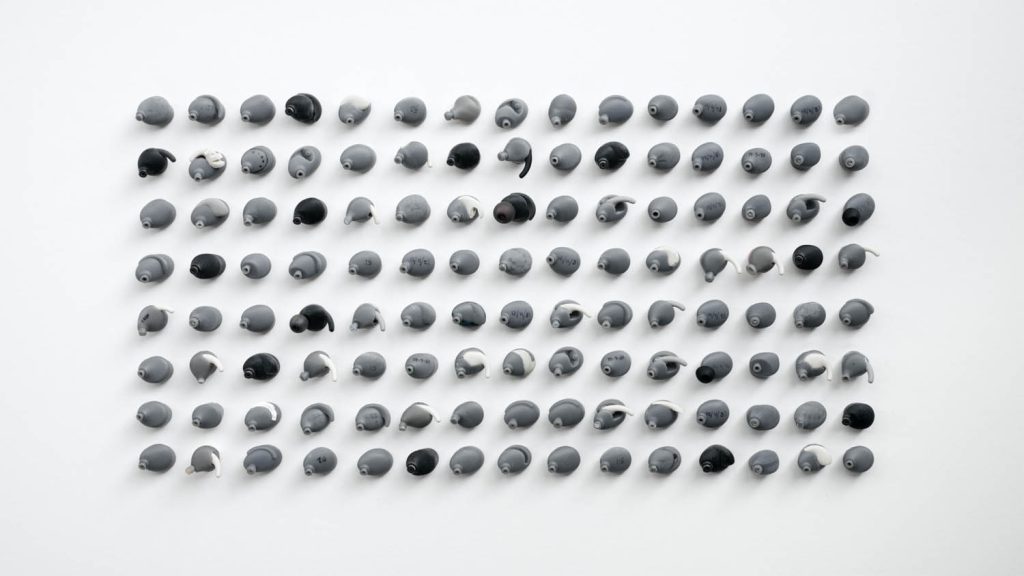

Elements of these prototypes were refined using hand tools, helping the designers to home in on a design, but also throw in different concepts quickly. The process was rigorous. When the first 20 models failed to provide a comfortable fit for everyone, tests with critical users quickly accelerated to 120 models and beyond.

“We had various philosophies on how to develop the ergonomics of the buds to start off with – almost paths that we were following – and we were using these [critical users] to filter them out,” explains Hartshorn.

“So we kept narrowing down, and then, once we started to get these candidates, which were benchmarked against competitors, we could then run this out to hundreds of people.”

In fact, the project was not just about designing earbuds, but also about designing a process to develop the earbuds. “And that was really fascinating to work on! We could just see, day by day, week by week, the gains we were getting and the improvements.”

Goodwin adds: “We realised that we were getting onto something quite special, because more and more people were saying how comfortable the earbuds felt. Our engineering background really underpins us, and often we’re working from the inside out when we’re developing our designs. In this instance, we were working from the outside in. Having developed this ergonomic platform, we then moved onto developing the industrial design.”

Watch Goodwin Hartshorn’s DEVELOP3D Live presentation

Go behind the scenes at Goodwin Hartshorn with their main stage presentation from DEVELOP3D LIVE 2025. See the team talk about the effort that went into developing Bowers & Wilkins’ latest award-winning earbuds from start to finish.

Get physical

Creating physical prototypes often helps the Goodwin Hartshorn team build objects that offer more than their initial function. Once in the hand, shapes become more than simple aesthetics. Even with mountains of earbuds 3D printed on the Formlabs machine, hand-sculpted foam double-scale models were still used to try and work out delicate features and balancing the shapes.

“We strongly feel you should be [building physical models] before you create your first CAD model, because as soon as you create the CAD model, you’re stuck in a reality that has been created on a digital screen, where your sense of scale is all over the place,” says Hartshorn.

“Having said that, I think we’re at a point now where you can often create CAD models much more quickly, so you can 3D print things and so on. That equation is changing. Often now, it is more about hacks.”

And there is no shortage of ‘hacks’ on display at Goodwin Hartshorn’s design studios in Deptford, South London, as the co-founders open boxes and boxes of early prototypes from other projects. These include wood and card models, handles and touchpoints carved from foam, built up with modelling clay or with pieces of milled brass added.

A prime example is the studio’s work on a surgical stapler, whereby it evolved an existing tool to not only incorporate better ergonomics, but also to make the entire process of loading it and priming it far more intuitive for the user.

“It can be that you’ll get a real, physical product, and you’re just Dremelling out a little bit, splicing in a bit of wood or brass, just to prove a point,” says Hartshorn. But putting it into the hand of the client next to a render on a screen helps the team imagine a finished product more easily. “It doesn’t lie. There’s no smoke and mirrors to it. There’s a physical object. And if they can use that physical object, you know you’ve proven the point.”

Colour, material, finish

Incorporating the physical alongside the digital is also key for developing the CMF (colour, material, finish) aspects of a design. In the case of the Bowers & Wilkins Pi6 and Pi8 earbuds, a wide range of possible colours would need to be considered, in order to maximise the product’s appeal for a global audience.

For Goodwin Hartshorn, collaboration software Miro acts as an infinite whiteboard where renders and lots of other imagery and notes can be added. The earbud project involved adding over 2,000 Keyshot product renders to its Miro canvas, helping the team work down to the final four colourways for the two earbud models, while the whiteboard even helped them to explain how they made the decision to the client.

“Previously we used Maxwell Render, but where renders were taking hours and hours, with Keyshot they’re taking seconds,” says Goodwin. “We might be doing renders that take 10 seconds, but that’s enough time for us to simulate different colours and finishes on the buds.”

Despite the high fidelity of the Keyshot renders, the Goodwin Hartshorn co-founders feel there’s still a need to communicate colours and materials physically with clients and manufacturers. In situations like boardroom presentations, or ensuring factories and suppliers can produce the finishes accurately across multiple materials and processes, having physical samples helps remove any false assumptions.

Hartshorn explains that a key reason is that everyone’s computer screen and calibration is different. Big boardroom presentation screens are typically among the worst for displaying colour, saturating it in weird ways, so that everybody ends up with a different sense of what that colour actually means, states Hartshorn.

To conquer this, the team have CMF plaques produced in the exact colours and roughly proportionally to the amount of surface the finished product would display.

Some are tubular, allowing the light to reflect with a curvature more natural to that of an earbud, while other plaques have gentler curved surfaces alongside metallic tubes, better for explaining headphone touchpoints.

Hartshorn explains that these stacks of colours, materials and finishes are brilliant for working out combinations of colours, particularly when the final industrial design is still to be signed off , but the studio wants to demonstrate to stakeholders how it will look when combined.

“You then subsequently start making decisions about how polished you want the arm to look – you don’t necessarily want it to look too ‘in your face’ – and you’re also trying to balance things or choose one element to stand out or not. So it’s about setting levels,” he says.

Each sample stack is nestled in a small black jewellery box with all the relevant data, such as Pantone numbers. Goodwin continues to talk while pulling more from the drawers of a long storage cabinet: “You’ve got the renderings there, but then when you get these in your hands, you can tell which really works!”

There is some prototyping magic involved along the way, he explains, with soft fabrics and leather often slow and costly to be dyed accurately in small quantities, so instead, a casting is used of the material and sprayed to give a realistic finish.

With more than seven boxes made for each colourway – one for the studio’s own office, one for Bowers & Wilkins offices, another for its factory in China, and the rest for the suppliers of other elements – two huge desks located in the studio can quickly be overtaken by samples and prototypes.

“You never focus down immediately on the final variant in terms of colour,” says Goodwin. “You’ve got two or three that get launched, and you’ve got some extra ones that come out [down the line]. But in order to develop the extra ones and the original ones, you’ve got a broad range. So we have loads of these different colours that never see the light of day.”

Which is to say that more products are already in development. In fact, during our visit, the latest over-ear Bowers & Wilkins Px7 S3 headphones are released.

Naturally, that prompts the co-founders to show me a pair of prototypes made while the new headphones were being designed. They highlight, for example, the slimmed ear cup, which has the effect of reducing the space that exists between the arms of the headband and the wearer’s temple.

This tweak to the ‘temple gap’ makes the headphones more comfortable and the experience of wearing them less noticeable for the user. The choices of colour, finish and details, meanwhile, speak volumes about the studio’s luxury, high-end ambitions for the product.

Once again, we see here a blend of excellent function and detailed aesthetics that is comfortably a calling card of Goodwin Hartshorn.

Bright Space, bright ideas

Entering Goodwin Hartshorn’s bright office space in Deptford, South London, visitors quickly encounter a striking line-up of tall Bowers & Wilkins floorstanding speakers, curated furniture, and walls covered in shelving filled with examples of the company’s client work and sources of inspiration.

A long, modular system of USM Haller storage drawers in golden yellow run along one wall, neatly housing box upon box of physical prototypes.

Due to the range of projects and products that Goodwin Hartshorn works on, hands-on physical prototyping is a key part of the process, influencing the designers’ troubleshooting and ideation.

Aside from Bowers & Wilkins, the company has developed a wide range of products for other companies, from precision surgical staplers for major medical brands to fun kitchen utensils for Joseph Joseph.

Among the archived boxes filling the drawers is a set of prototypes for a cutlery project. Both the founders have a clear love for form and function of knives, forks and spoons.

Cutlery, according to Goodwin, “is really fascinating in the same way as, I guess, chairs, lighting and fonts. The function of the object is just so assumed that what you get is the pure design. You almost don’t clock that this is a method for passing on information. I think cutlery is similar.”

Much of the design for this cutlery set was hand-sculpted, in order to attain the fine details of each angle, the depth of the spoon’s ‘bowl’, and to embody the angles of a ‘superellipse’ throughout the set. The prototypes were built using metals 3D printing before being post-processed, and they line up beautifully on the desk.

Says Hartshorn: “The shape of a knife is fundamentally different, for good reasons, from that of a spoon. They’re doing two different things, as is a fork, which is going to stab stuff. You’re trying to develop an identity for them that is harmonious, yet which respects the different functions.”

More prototypes are produced, this time showcasing Goodwin Hartshorn’s work for Joseph Joseph – an early client, thanks to a recommendation from designer Mark Sanders, their former tutor at the Royal College of Art. Sanders is himself a designer of iconic Joseph Joseph products, such as its Chop2Pot folding chopping board.

An early brief was for a device to crush garlic. “That was the brief: it just needs to stand out,” laughs Goodwin, as a box of prototypes is unpacked.

The initial concept was a tube in which cloves of garlic were placed, with a plunger to push the garlic up against a grate, crushing it. However, the force needed to push the garlic made this a two-handed job, which led to the designers adding arms to the design, along with a rocking action to help the task along. In this way, the Garlic Rocker was born.

From this functionality, it then became about further honing the design and surfaces, adding curves and recurves along with different thicknesses to make the rocker more sculptural, as well as easier to hold and use.

Once pressed, the designers realised the garlic sits on top of the grate and can be tipped straight into a pan, while its stainless-steel construction means it can be used as a garlic soap, in order to remove the odour from your hands.

These forms were developed with hand-sculpted foam models and then built in 3D CAD using Solidworks. Having overcome some initial manufacturing challenges, the Goodwin Hartshorn Garlic Rocker for Joseph Joseph proved a great success and has become an icon among kitchen utensils. Yet its success has attracted masses of copies, some of which occupy a dedicated shelf in the Goodwin Hartshorn office.

“It was surreal for us!” laughs Hartshorn as he works his way down the line of impersonators. Together, they form a timeline. Some early copies are just basic versions of the Garlic Rocker, built from cheaper materials.

Later copies incorporate pseudo functionality such as bottle openers or slicers. More recently, larger brands have launched their own variants, approaching the product in the same way as they might an age-old, established utensil.

What’s key is that none of these copies can rival the original, either in terms of form or function. However, it’s a striking reflection of the market forces that successful designers everywhere must combat.

This article first appeared in DEVELOP3D Magazine

DEVELOP3D is a publication dedicated to product design + development, from concept to manufacture and the technologies behind it all.

To receive the physical publication or digital issue free, as well as exclusive news and offers, subscribe to DEVELOP3D Magazine here