The new Color Resin V5 from Formlabs will allow users to order customised colour resins in quantities as little as one litre to be produced in one week, allowing for SLA 3D printed parts in brand or custom colours.

Only available in the USA, with expansion to other regions promised for the near future, Color Resin V5 is the newest addition to Formlabs’ General Purpose Resins for the Form 4 Series 3D printers.

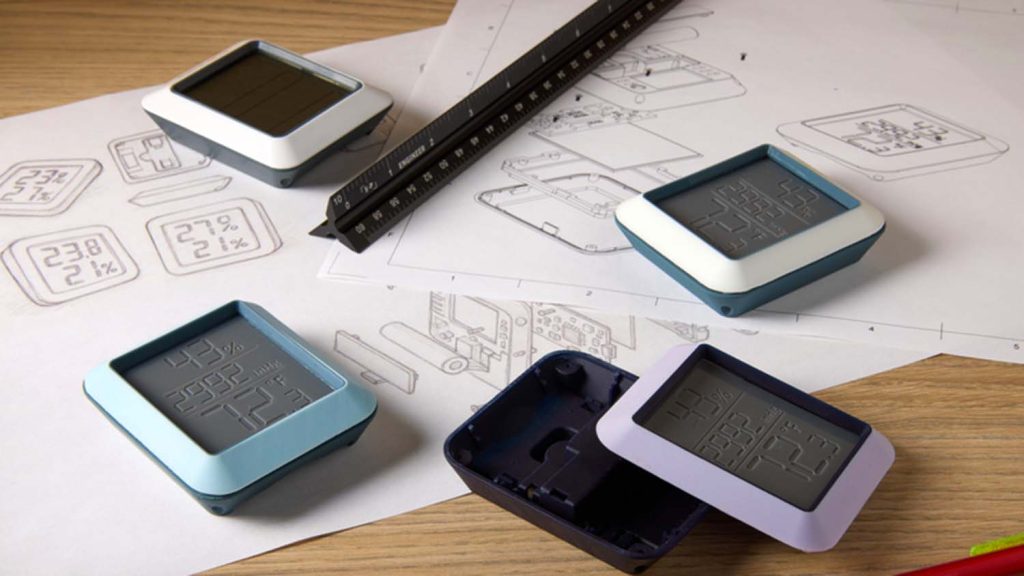

By avoiding outsourcing, painting, or alcohol-dyeing — all of which require lead time, additional material, and labour – Formlabs is hoping the service will allow more custom colour SLA 3D printing, achieving everything from nuanced neutrals to saturated, bold colours with the same process of printing any other General Purpose Resin.

Designed for both aesthetics and performance, Formlabs says that the mechanical properties of Color Resin V5 are ‘commensurate’ with General Purpose Resins for Form 4 Series 3D printers, with a small amount of variability depending on the colour ordered.

To order Color Resin V5 in custom colors, users can enter Hex codes or RGB profiles via the store page, which will show you your requested colour and the closest achievable colour.

Also announced is a new True Cast Resin for 3D printing detailed patterns up to 5 mm thick. Formlabs says that the True Cast Resin integrates with a wide range of burnout schedules with low thermal expansion, minimal shrinkage, and 0.03% ash content to ensure clean burnout and consistently excellent casting outcomes.

Additional updates to PreForm print software should make it easier to set up parts for printing while giving expert users more nuanced controls. Face Selection Mode for the PreForm Texture Tool enables users to select where texture is added; Part Color Coding improves tracking and visibility in a packed build. A new, reduced support setting option enables 30 per cent reduced supports on select materials.

A Face Selection toggle allows a generated texture to be applied to a target face rather than the entire body. This control of texture generation enables improved aesthetics and functionality on desired surfaces without compromising other critical features in the model, like mating surfaces, snap fits or holes.

Additionally, the software allows for reduced supports – by as much as 30 per cent – allowing the user to optimise a print for fewer support touchpoints, cleaner supported surfaces and reduced post-processing. More challenging geometries may still need to be reoriented to avoid print artifacts.